Sustainability is part of

of our process.

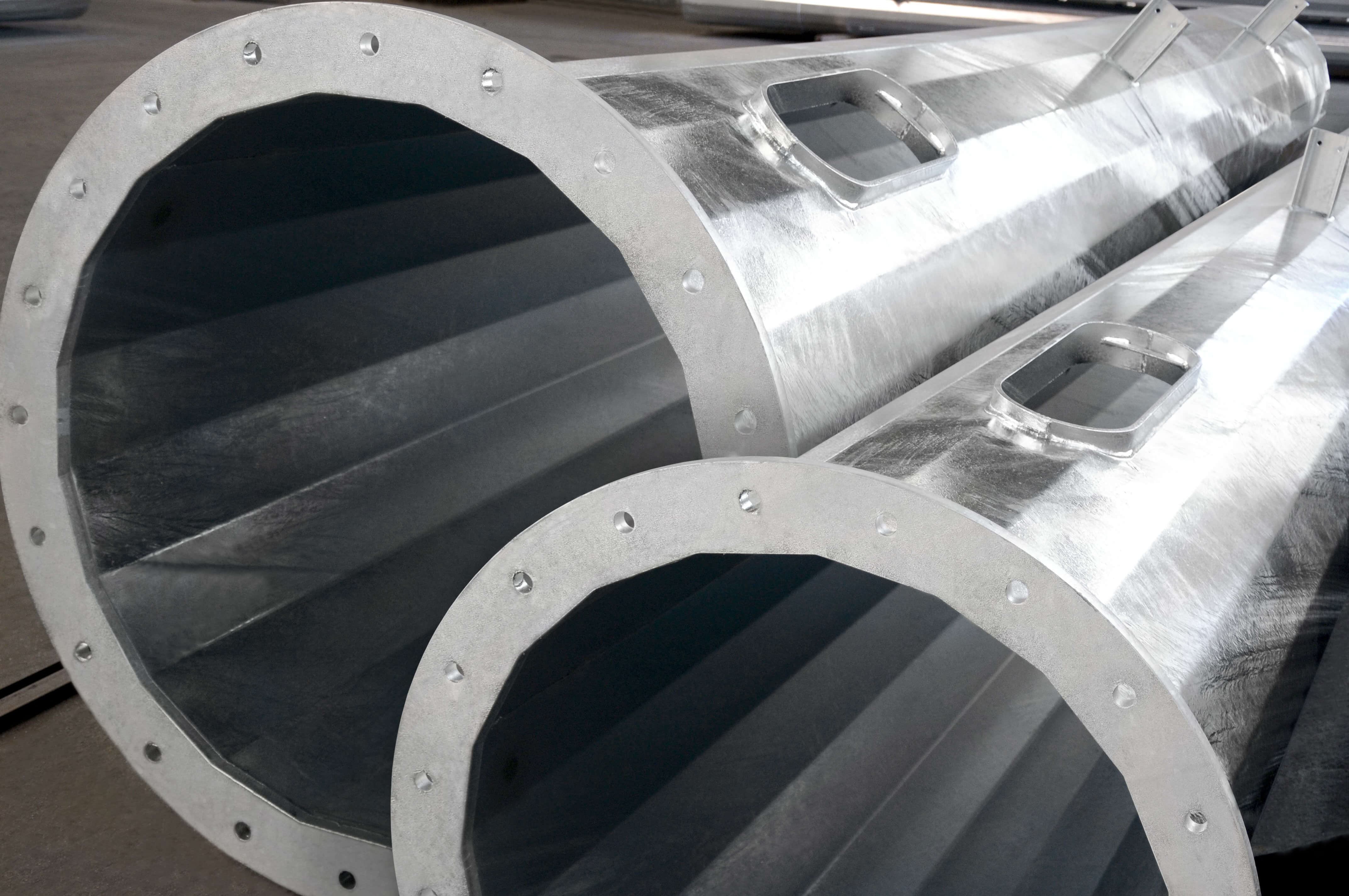

In this process the materials are protected from bad conditions and the product life is extended in time. Moreover, at the end of the life cycle the product can be completely recycled into a new fusion, without releasing any rust.

The main advantages of the hot dip galvanizing are:

Lower initial cost

Hot dip galvanization, in general, has very competitive costs when compared to other forms of protection specified in the steel protection. The cost of applying coatings that require intensive labour, such as painting, has grown more than the implementation costs (in factory) of hot dip galvanizing.

Small maintenance/ lower cost on a long term

Even in cases where the initial cost of the hot dip galvanizing is higher than the alternative coatings, the galvanization presents smaller maintenance costs over the life time of the component/ structure. The maintenance is even more expensive when the structures are located in remote areas.

Long life

The life expectancy of galvanized coatings applied to structural components exceeds 40 years in the most rural environments, and is between 10 to 30 years in the most aggressive, urban and coastal environments.

Superficial treatment

Superficial treatment the immersion in the acid, as pre-treatment, ensures the regular cleaning of the steel surfaces. By contrast, traditional organic coatings should be applied on clean surfaces with abrasive blasting (in general, according to norm ISO 8501-17, in level Sa 2 ½, or superior) and inspected. Additionally, the application of organic coatings is limited in terms of environmental conditions and humidity relative at the time of the application. This adds a cost in the application of a robust painting system.

Adherence

The coating obtained by hot dip galvanizing is metallurgically bound to the steel substrate.

Environmental contamination

The coating is non toxic and contains no volatile substances.

Speed in applying the coating. A protective coating is applied in minutes. A traditional paint system can take several days. The application of galvanized coating does not depend on the weather conditions.

Regular protection

All the surfaces of a hot dip galvanized component are protected both internally and externally, including rebates, corners and inaccessible areas to the application of other coating methods.