TESTED AND PROVEN PROCESS OF GALVANIZATION.

The hot dip galvanizing is a process of applying zinc coatings to components in steel or iron by immersing the component in a bath of molten zinc.

The simplicity of the hot dip galvanizing process is an advantage on other methods of corrosion protection.

Our process is divided into the following steps:

1. Cleaning – Bath in acid solution to remove oils, masses and other greases.

2. Rinsing – Washing realised to avoid contamination of the following bathes.

3. Pickling – Bath in hydrochloric acid to remove oxides and mill scales.

4. Rinsing – Washing realised to avoid contamination of the following bathes.

5. Fluxing – Solution of zinc chloride and ammonium chloride which acts as protection against oxidation between the pickling and zinc immersion.

6. Drying – Stage in an oven at 60ºC to dry the pieces and reduce the thermal shock upon immersion in the zinc bath. Furthermore acts as wetting agent of the pieces in the zinc bath.

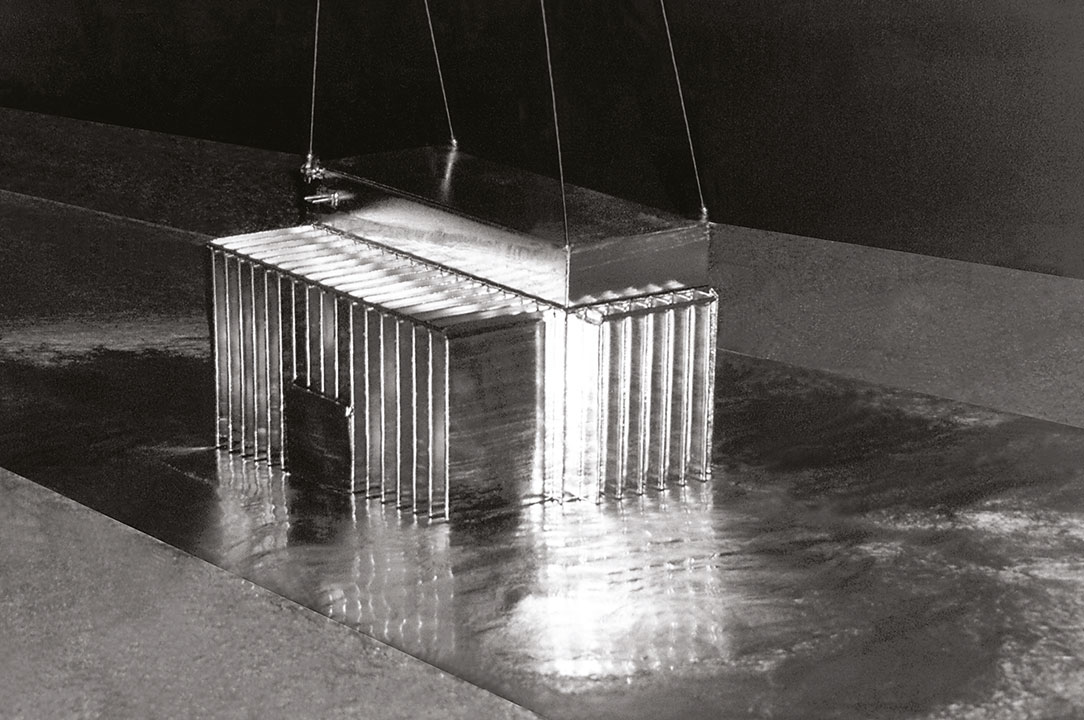

7. Zinc bath – Immersion in a bath of molten zinc between 440º and 465º to reaction between Fe/Zn which composes the final coating.